Search

People also search for:

Why Vibrating Screens Are Pharma’s Top Choice: 4 Key Advantages Beyond Cleanliness

Seamlessly connect with your tools and streamline workflows to enhance efficiency and performance.

Why Vibrating Screens Are Pharma's Top Choice: 4 Key Advantages Beyond Cleanliness

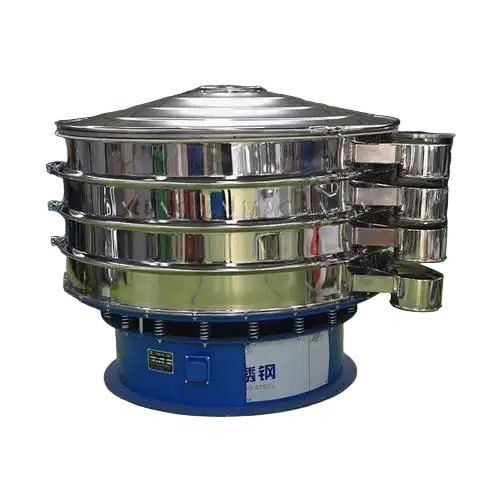

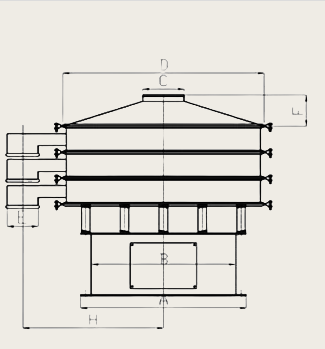

Vibrating Screen (Also Known as 3D Vibratory Sifter): The High-Precision Screening Solution for Pharmaceutical Powders

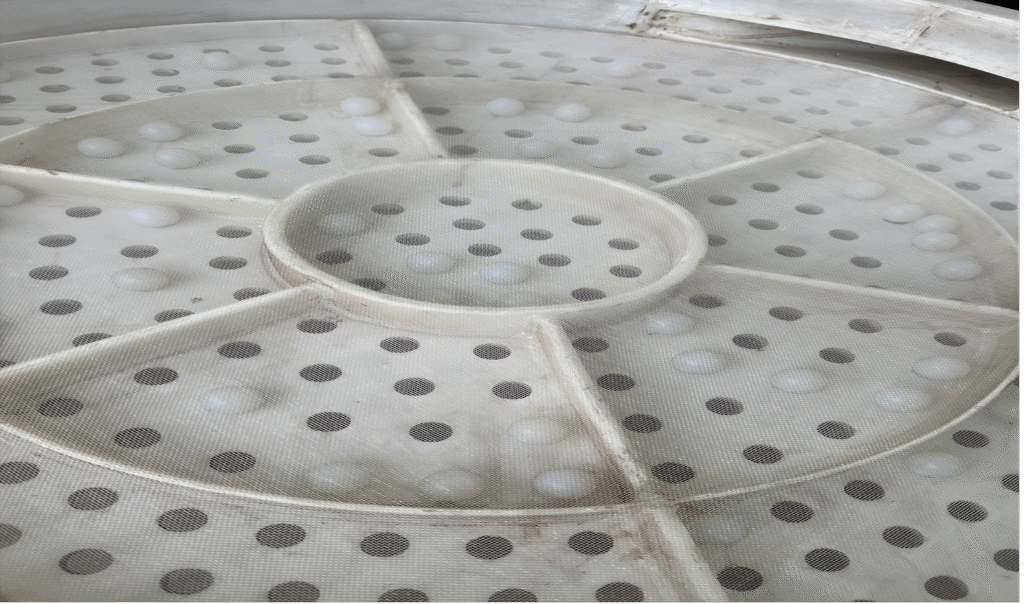

Its core advantage lies in the unique design of its vertical vibration motor—eliminating the risk of lubricant leakage common in traditional horizontal motors (meeting pharmaceutical “contaminant-free” requirements). Equipped with eccentric weights at both ends, the motor converts rotational motion into three-dimensional movement (horizontal, vertical, and tilting), transmitting precise vibrations to the screen surface. This motion pattern not only extends material dwell time but also maximizes screen utilization, significantly enhancing screening efficiency.

Key Applications in the Pharmaceutical Industry:

- Solid Drug Particle Sizing

Vibrating screens are widely used for solid drug classification, where particle size distribution must meet strict specifications. With high-efficiency screening capabilities, they rapidly process bulk samples, accurately separating particles by size through precision mesh grading—a critical step in pharmaceutical quality control.

- Pharmaceutical Granule Processing

A core application lies in granule refinement during drug manufacturing. The vibrating screen precisely sieves raw materials to ensure uniform, stable particle size, meeting formulation requirements. It also enables multi-grade classification, streamlining downstream production.

- Liquid Filtration for Intermediates

In pharmaceutical liquid processing, vibrating screens remove impurities (e.g., particulates, microbes) from suspensions and slurries. Their specialized screen structure and ultra-fine meshes guarantee filtrate purity and safety, even with high-viscosity fluids.

Vibrating Screen’s Fully Enclosed Design

The hermetically sealed structure effectively contains dust emissions and prevents liquid leakage, safeguarding operator health and environmental compliance.

Powder Classification in Pharmaceutical Intermediates

Precise particle size distribution and impurity control are critical in pharmaceutical powder processing. The vibrating screen delivers fine powder sieving and dedusting to meet stringent production standards. With quick-change screen panels and high-throughput efficiency, it significantly optimizes manufacturing productivity.

Vibrating Screens in Pharmaceutical Intermediate Manufacturing: Key Advantages

Vibrating screens offer multiple critical benefits in pharmaceutical intermediate production:

1) High Efficiency with Low Noise – Achieves rapid screening with minimal operational disturbance

2) Fully Enclosed Design – Maintains cleanroom-compliant containment for hygienic processing

3) Precision Grading – Meets exact particle size and purity specifications for diverse materials

4) Easy Maintenance – Reduces downtime and operational costs

Pharmaceutical Applications

Widely deployed across:

- Solid APIs & herbal extracts

- Powder/liquid formulations (both TCM and synthetic drugs)

- Granule processing for combination therapies

By ensuring material consistency and eliminating contaminants, these systems enhance drug purity, stability, and therapeutic efficacy. As the pharmaceutical industry evolves through cross-sector collaboration and technological integration, vibrating screens will remain indispensable for advancing manufacturing standards.

1 Comment

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.